WELDING CABLES / SUBMERSIBLE CABLES

Application

Application

For the transmission of high currents from the electric welding machine to the welding tool. Suitable for flexible use under rough conditions, on assembly lines and conveyor systems, in machine tool and motor car manufacturing, ship building, for manually and automatically operated line and spot welding machines.

Standards

As per BS638 Part 4

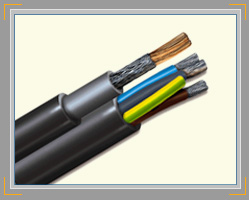

Conductor

Class 6 extra flexible plain copper conductors to BS EN 60228:2005 (previously BS6360)(Class 5 flexible plain copper conductors for 120mm2 and above)

Insulation

EPR (Ethylene Propylene Rubber) to BS7655

Sheath

HOFR (Heat and Oil Resistant and Flame Retardant) Sheath to BS7655

Sheath Color

Black

Voltage Rating100V (450V for non-welding applications if suitably protected from mechanical damage)

Temperature Rating-20°C to +85°C

No. of Cores x Nominal Cross Sectional Area |

No./Dia. of Strand |

Nominal Thickness of Insulation |

Nominal Overall Diameter |

Nominal Weight |

x mm² |

No. / mm |

mm |

mm |

kg/Km |

1 x 16 |

512 x 0.21 |

0.9 |

9.7 |

215 |

1 x 25 |

800 x 0.21 |

0.9 |

11.2 |

305 |

1 x 35 |

1120 x 0.21 |

0.9 |

12.4 |

400 |

1 x 50 |

705 x 0.31 |

0.9 |

14.3 |

587 |

1 x 70 |

990 x 0.31 |

0.9 |

16.3 |

775 |

1 x 95 |

1340 x 0.31 |

1.0 |

18.6 |

1040 |

1 x 120 |

1690 x 0.31 |

1.0 |

20.3 |

1256 |

1 x 150 |

2123 x 0.31 |

1.1 |

22.6 |

1360 |

1 x 185 |

1470 x 0.41 |

1.2 |

24.7 |

1875 |

1 x 240 |

1905 x 0.41 |

1.3 |

27.8 |

2534 |

Construction

Construction